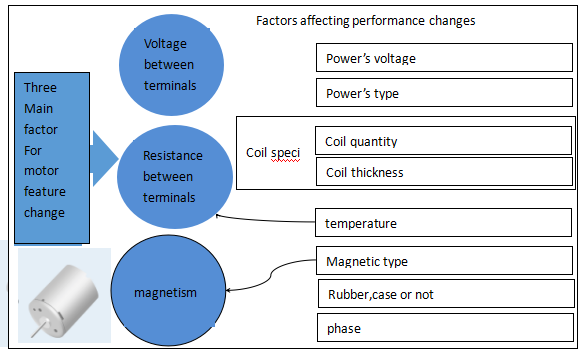

What's the factor affect

performance change

The Main factors that affecting micro DC motor performance changes

The performance of a motor is determined by three major factors:

- voltage between terminals

- resistance between terminals

- magnetic force.

Here, we will provide specific examples to illustrate the various main factors that have an impact on these main factors, namely the deterioration of DC motor performance.

Voltage for DC motor performance changes:

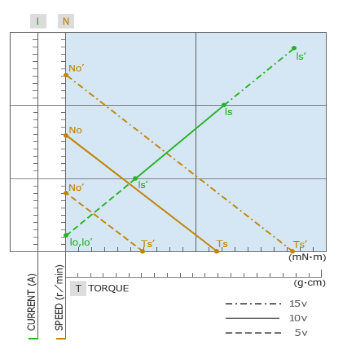

Only when there is a change in the voltage of the power supply can the performance be directly proportional to the change in voltage.

As shown in the image, when the voltage changes due to the power supply, the rotating line moves in Parallel transport, and the current line almost changes in a straight line.

However, beyond a certain limit, it is no longer proportional to the voltage.

Power type for DC motor perfomance change:

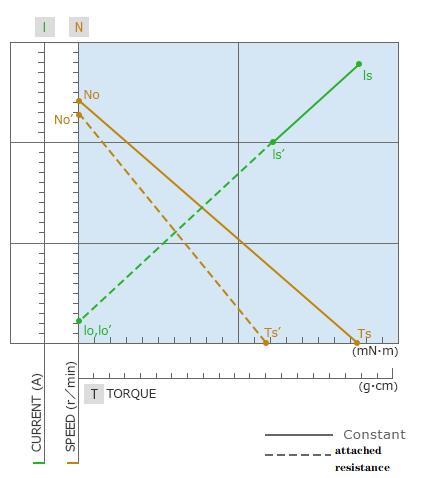

Comparing a Constant power supply with an attached resistance power supply (a power supply with internal resistance r),

the attached resistance power supply will experience a voltage drop with the internal resistance r.

The stopping current will initially decrease, and the stopping torque will also decrease, causing a change in the inclination of the rotating line.

Internal resistance of manganese battery (1.5V) | |

Unit 1 type | 0.15~0.20 (Ω) |

Unit 2 type | 0.25~0.35 (Ω) |

Unit 3 type | 0.40~0.50 (Ω) |

Remarks:A motor can be defined by a generator that generates a voltage proportional to the number of revolutions, as well as a motor terminal resistance in series with the voltage.

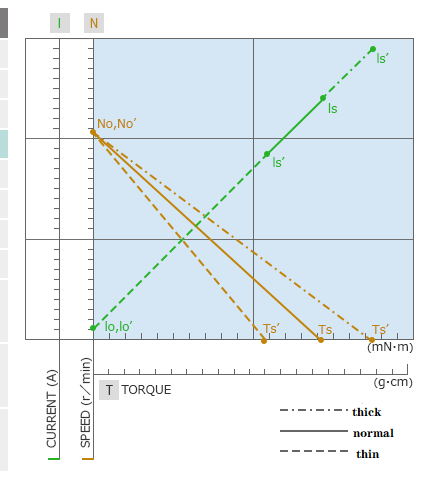

Coil for motor perfomance change:

What has a significant impact on motor performance is the coil size.

When there is a change in the number of coils and the diameter of the coil, the results are different.

If the number of coils is increased, the no-load speed of the motor will decrease proportionally.

If the diameter of the coil is thickened, the stopping torque and stopping current of the motor increase proportionally to the square of the coil diameter.

However, beyond a certain limit, it is no longer proportional to the square.

Conditions for changing the winding line with the same model

When changing the winding line with a motor of the same model, it is necessary to use similar line product values.

Line product value= φ 2 (twice the diameter of the coil wire) × N (number of coils)

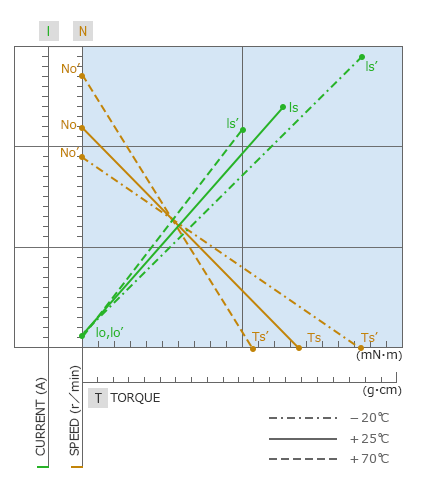

Temperature for motor perfomance change:

The ambient temperature can affect the magnetic force and coil resistance of the magnet. Therefore, there will also be changes in motor performance.

The degree of change at every 1 ℃ change

| ||

The magnetic force of a magnet | ferrites | -0.19% |

Rare earth magnet | -0.13% | |

Coil resistance | +0.39% | |

Additional explanation: The impact on the 4-point performance of the motor when the temperature increases

N0: No load RPM

In inverse proportion to the weakening of the magnetic force of the magnet, N0 increases.

I0: No load current

It is inversely proportional to the magnetic force of the magnet, but the loss caused by changes in the viscosity of the bearing oil has a greater impact on I0.

Therefore, our company assumes that I0 is not affected by temperature changes when making presumptive calculations.

Is: stopping current

Inversely proportional to the coil resistance, if the temperature rises, Is will decrease.

Ts: Stopping torque

Due to the weakening of the magnetic force of the magnet, the current will decrease. Therefore, if the temperature rises, Ts will significantly decrease.

List of Main Factors for Returning to Changes

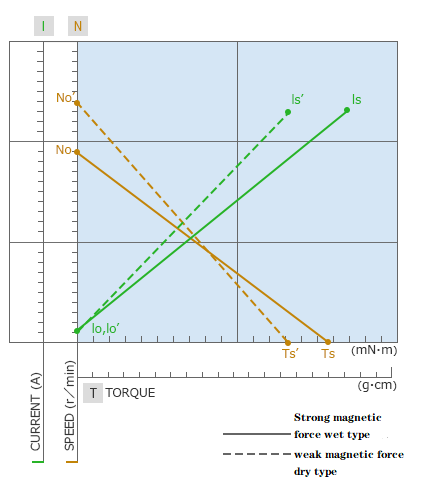

Types of magnets for motor performance change

There are also various types of magnets, mainly referring to changes in magnetic force.

Because when changing from a wet heterojunction magnet to a dry heterojunction magnet, the magnetic force will weaken,

causing a decrease in the stopping torque (Ts) and an increase in the number of unloaded rotations (N0).

case for for motor performance change

In terms of the ability of magnets, when the metal shell that maintains the magnetic force is thin,

the magnetic force will leak out of the shell. The so-called auxiliary casing refers to preventing magnetic leakage in order to ensure the ability of the magnet.

The value of a will vary depending on the leakage degree of the motor's magnetic force or the thickness of the auxiliary casing.

The difference in the auxiliary casing in our company is approximately 8-12%, and it is considered as a=1.08-1.12.

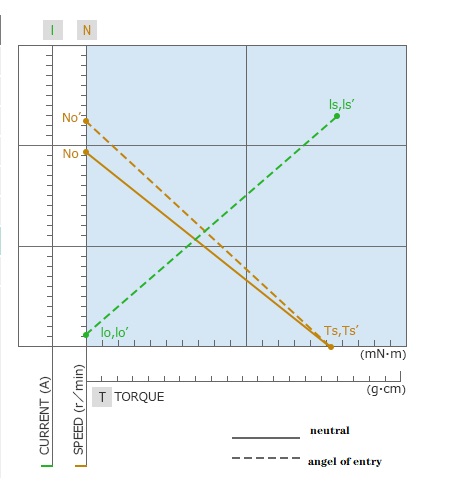

Phase for for motor performance change

Phase refers to the position relationship between the conversion position of the commutator and the brush and the center position of each magnetic pole of the magnet.

Even if the motor is assembled into a neutral phase in the early stages, during load operation, due to the phenomenon of rotor reaction,

it will become delayed phase (delayed angle) electrically for a period of time. Delayed angle is a poor condition for motors,

which will lead to deterioration in efficiency, electrical noise, lifespan, and other aspects.

As an improvement measure, the phase angle is assembled into an inlet angle,

which counteracts the rotor reaction during load rotation to maintain a neutral inlet angle motor electrically.

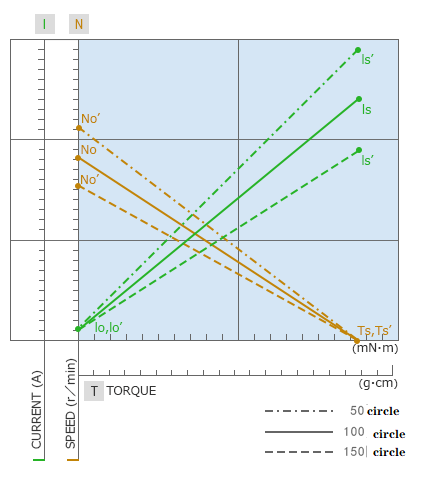

Set the neutral 4-point performance to (N0, I0, Is, Ts), and the performance of the inlet angle to (N0 ', I0', Is', Ts').

The performance of the inlet angle will be as shown in the above figure, with a slight increase in no-load speed N0 ',

while other performance is generally similar. When the variation of N0 'is 12-15 °, the angle of entry is 6-8%.

However, when calculating Ts based on the intermediate torque performance, the angle of entry may become relatively small.

Points to note about the angle motor

If the angle motor is reversed in this state, it will become a delayed angle, leading to deterioration of the rectification effect,

and adverse factors in terms of electrical noise and lifespan. Therefore, the direction of rotation must be unidirectional.

More information of DC motor,pls refer to: